My bathroom exhaust fan died. I have a Nutone fan, and the old fan was larger in size than the newer fan models. I rushed to the store to buy the fan, and bought a BKR60 shroud - but the problem was the new brackets that come with it didn't matchup with the existing bracket.

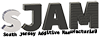

Old Bracket

This would not work on the new bracket, so what I did was measure the diameter, import it into CAD, and size it appropriately to re-engineer it.

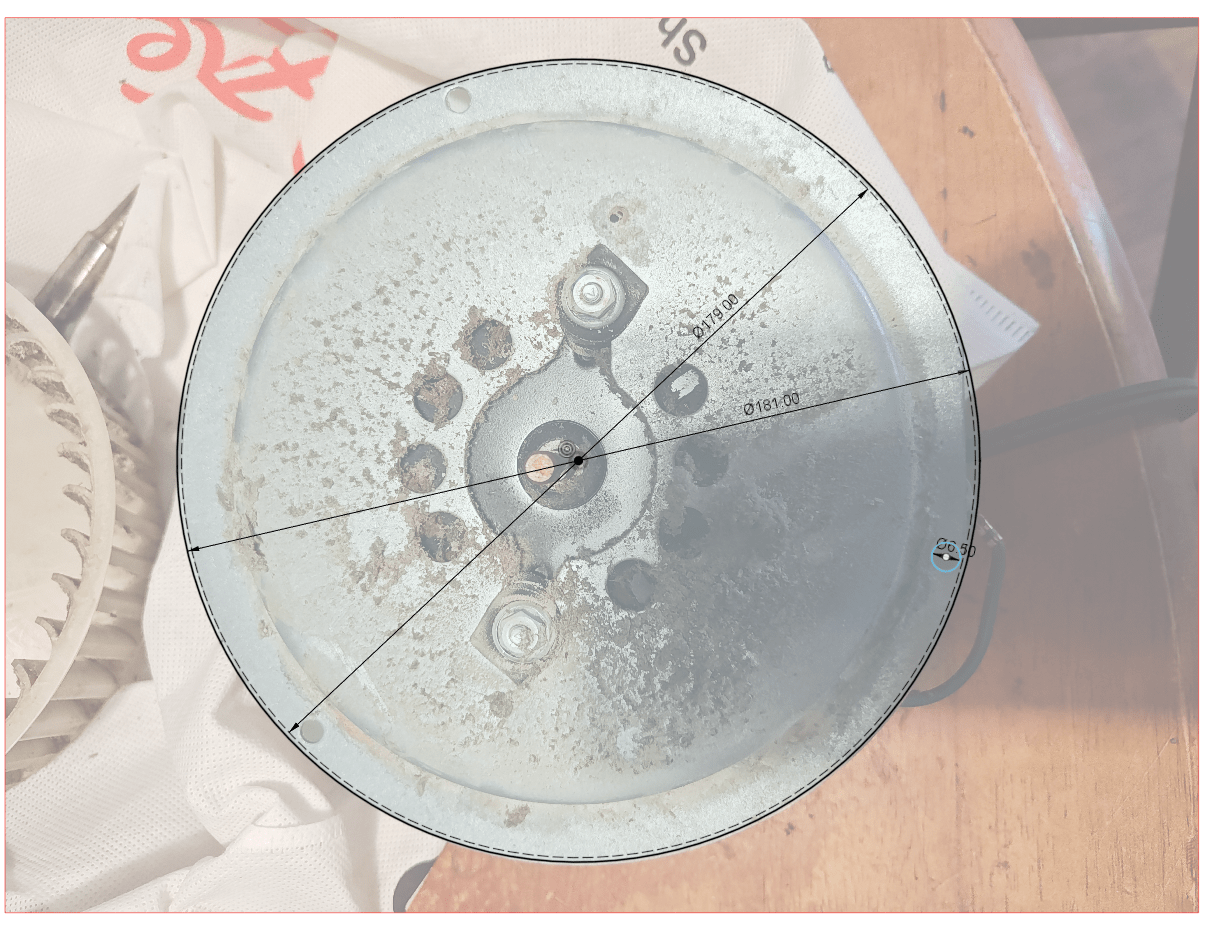

New Bracket

I could not fit the new bracket to the turbo type shroud of the fan, but I did need the internal geometry. So, I also imported this into CAD and sized it appropriately.

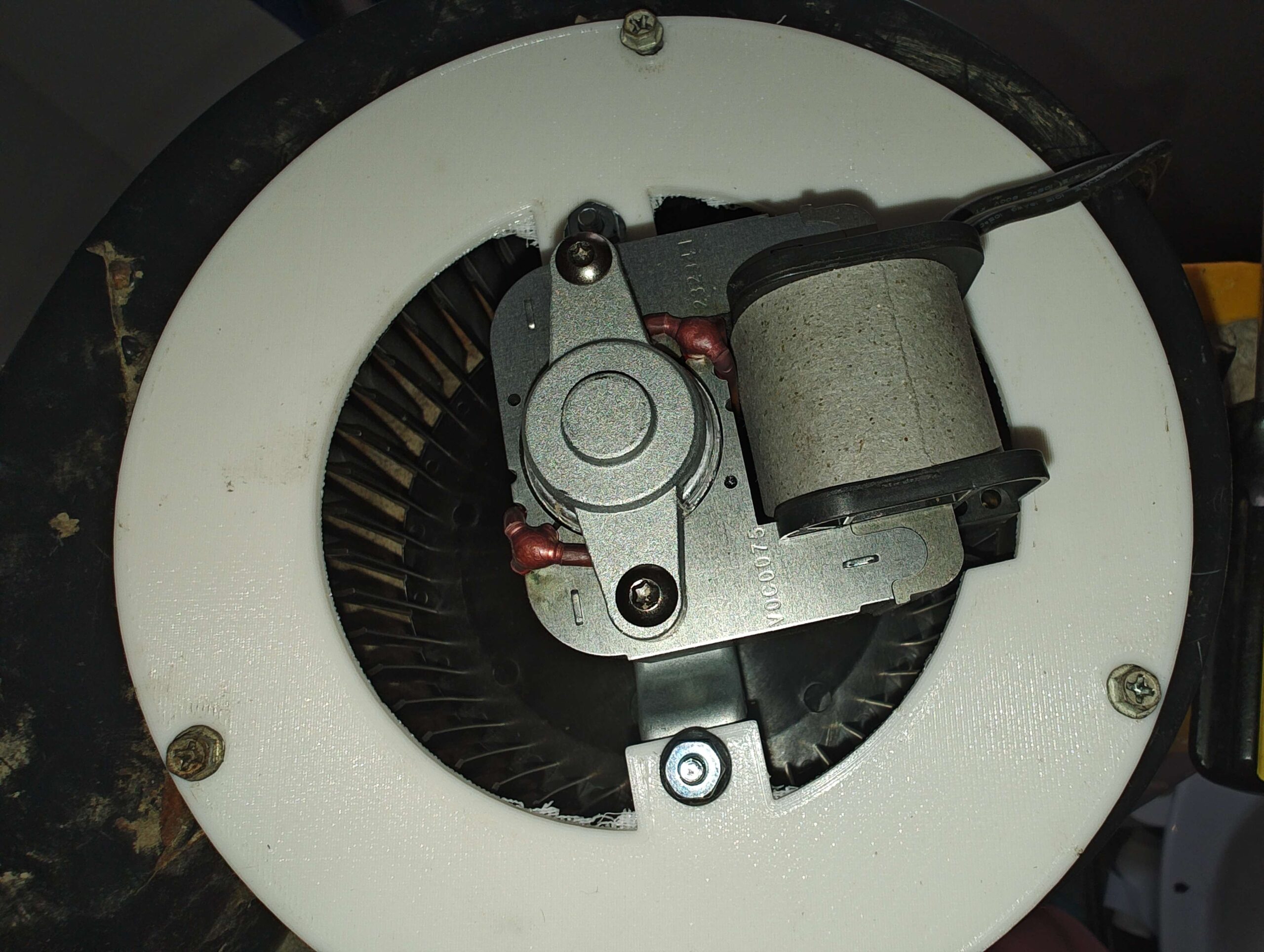

Result

Quickly printed something out of PETG, PETG is a co-polymer which is good at chemical resistance. This worked perfectly on the first try and took about 30 minutes of measurements and design work.

This is the type of work that can be done with a laser cutter but would not be cost effective. I solved a problem quickly and easily using Additive Manufacturing, and you can also.

Nutone fan fixture BKR60 shroud fixture by mcgg | Download free STL model | Printables.com I made this model open source for you to download.