Materials = Applications

Additive Manufacturing is getting new materials all the time, and variants with specific use cases of existing polymers. Some examples may be Zymergen Z2, a Polyimide with exceptional Z strength and heat resistance. Ultimately, datasheets help discern the properties of the polymers you can chose from, and it may be confusing to use a datasheet practically to drive your application.

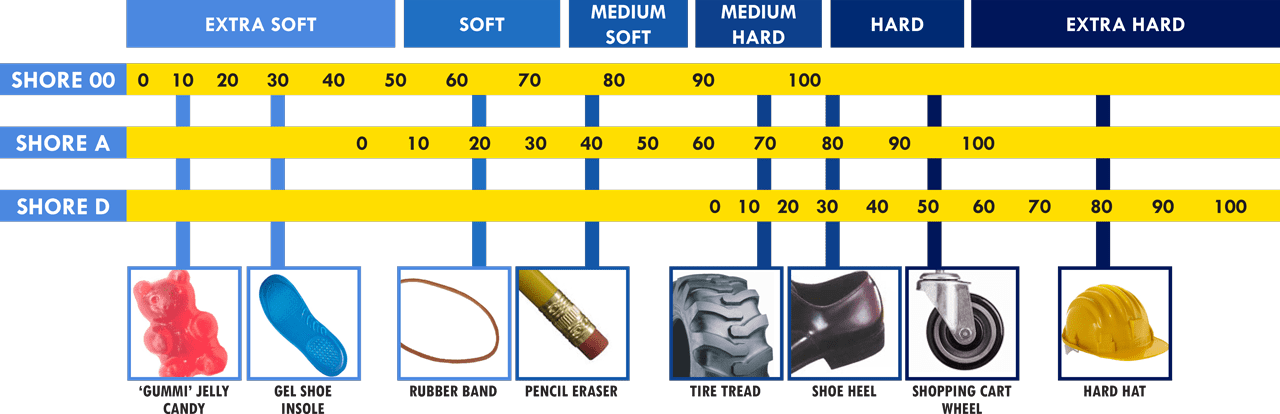

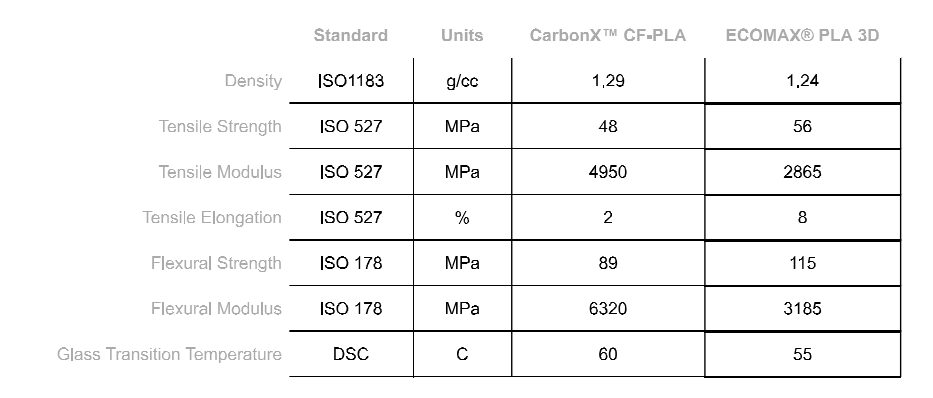

Before we start, we have one big caveat: there are testing standards such as ISO 527, and you must be apples to apples to compare them. Also if one number is in MPa(megapascal pressure unit) the other must be as well to keep it even.

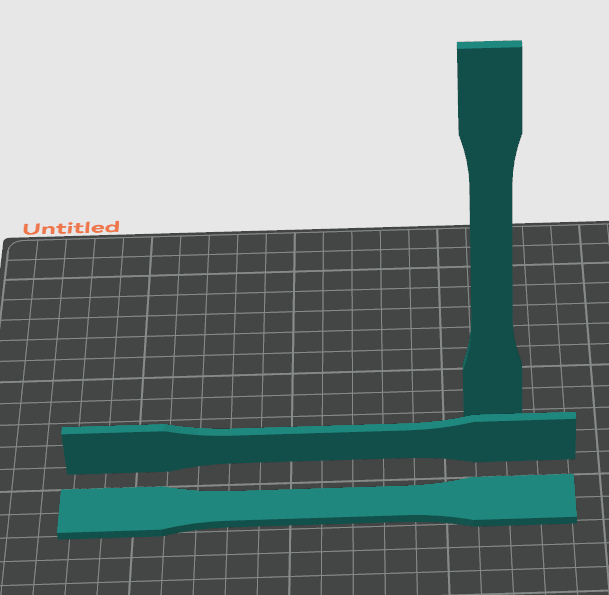

Most materials are tested with an ASTDM D638 specimen type 1 or 2, this may be called a dogbone. Companies who are utilizing sophisticated applications often ask for printer manufacturers to print dogbones in three configurations and test them - to get an idea what machine has the best process control to produce a strong part. Companies often characterize their material data sheets using this as well - but it can vary from machine to machine - quite drastically in some cases even where it seems like per spec sheet it should be comparable.

Information a sheet may show you

Data Sheet Comparison - PLA vs CF PLA(carbon fiber)

Above is a comparison of datasheets from 3dxTech. While I have not printed PLA in years this should serve as a good comparison as these are popular hobbyist materials. What can be discerned quickly is:

Carbon Fiber Adds a considerable amount of stiffness.

Standard PLA is more resilient as it has a higher tensile strength and higher flexural strength.

If you wanted the material to be more rigid, I would choose the Carbon Fiber variant. If you were going to abuse the part knocking it around - Standard PLA would serve you better

There is no "best material" and most people try to balance cost and properties. The key is to identify the use case, and then make a part out of a polymer that is best suited for the use.